This is pretty much every post that I made that was the least bit useful and/or helpful to anyone who is considering swapping an H22 into their 6th gen accord.

This thread has been severely pruned because doing this much took long enough. I can answer pretty much any question regarding this job, (and many others).

This information is all from my original thread on Everything-honda.com, which has unfortunately gone under. Another unfortunate event was the passing of imagestation.com;

which is where I had originally hosted all my pics. Some of which were uploaded directly from my camera, and never to my hard drive. So they are lost forever, .

.

I did my best to rehost and replace all the pics I could. I skipped some due to relevancy, others due to their absence.

I hope people find this information useful, its taken me all night to do.

01-24-2006, 10:00 PM

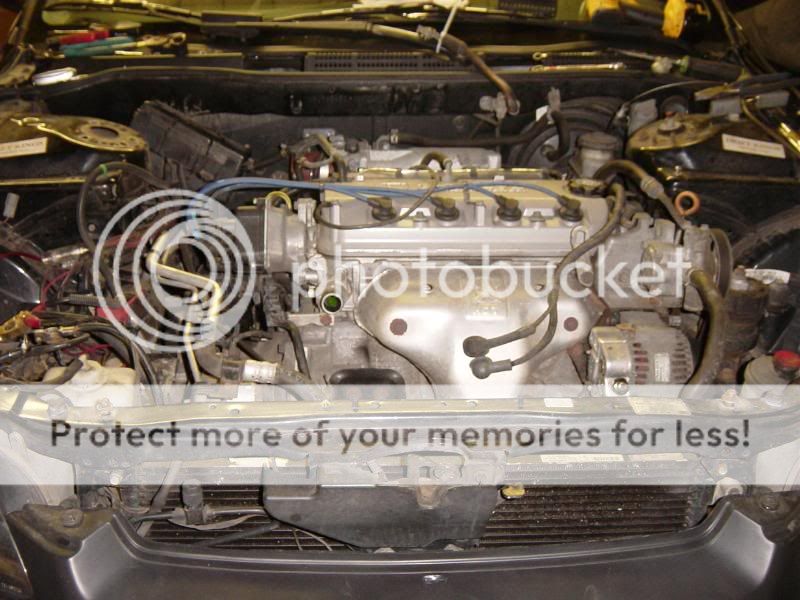

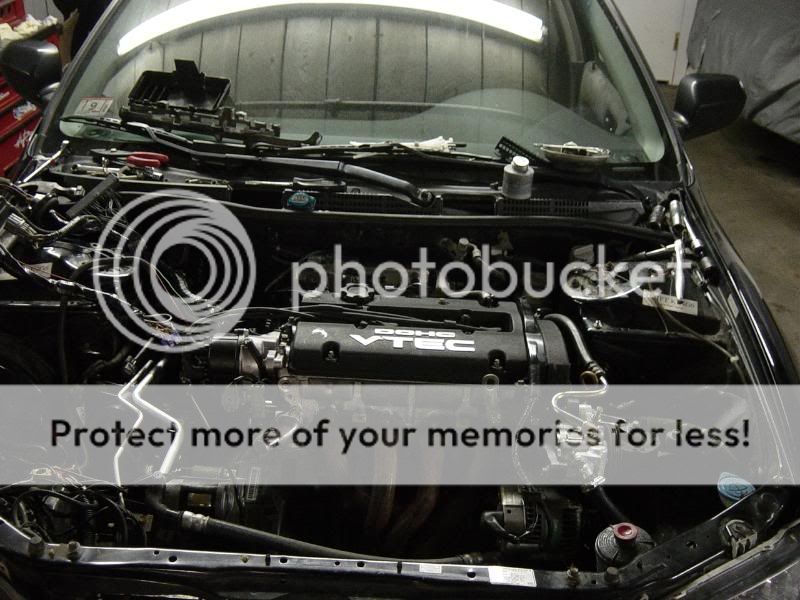

So the motor arrived today and it looks great. Steve at www.hmotorsonline.com hooked it up.

I was first told it was going to be out of a '93, but its actually out of a '95, Im not complaining.

JDM tIgHT yO!!1!1!

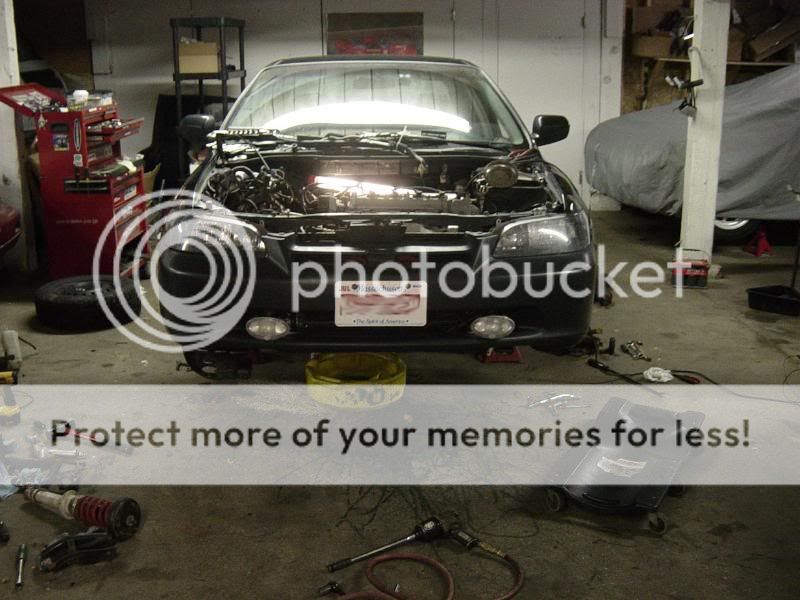

So today I took the tranny off and made sure it had the LSD, its did . I also took the pressure plate and clutch disc off to see what condition they were in. Used, obviously, but no bad at all. I took the die grinder with a sanding brush on it to the pressure plate and flywheel.

And the clutch disk still looks good. If my ACT is the same size, its going in the H22 though, no question.

After greasing up the input shaft, throwout bearing, and clutch fork again, I put the tranny back on.

As I was doing so, I say this:

The two lines coming out of the tranny, as I later found out, are for the Rear Wheel Steering. I may use it for a tranny cooler later down the line.

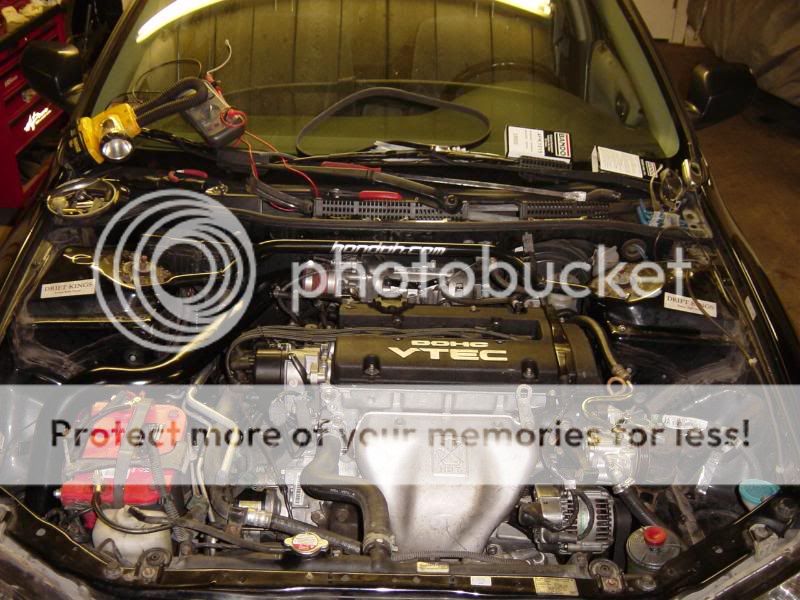

This is the motor mount that is different from the F23 mount. I am going to make a custom one to replace it.

Skunk2 Hooks it up again.

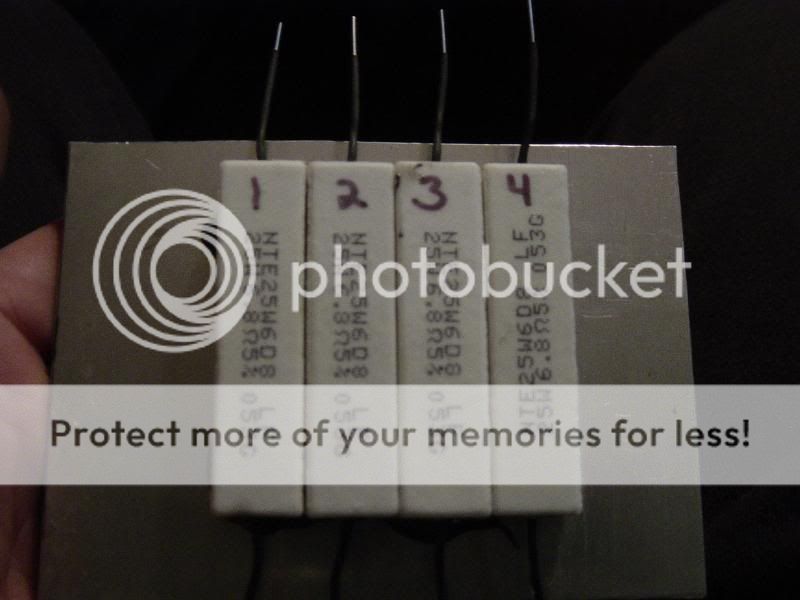

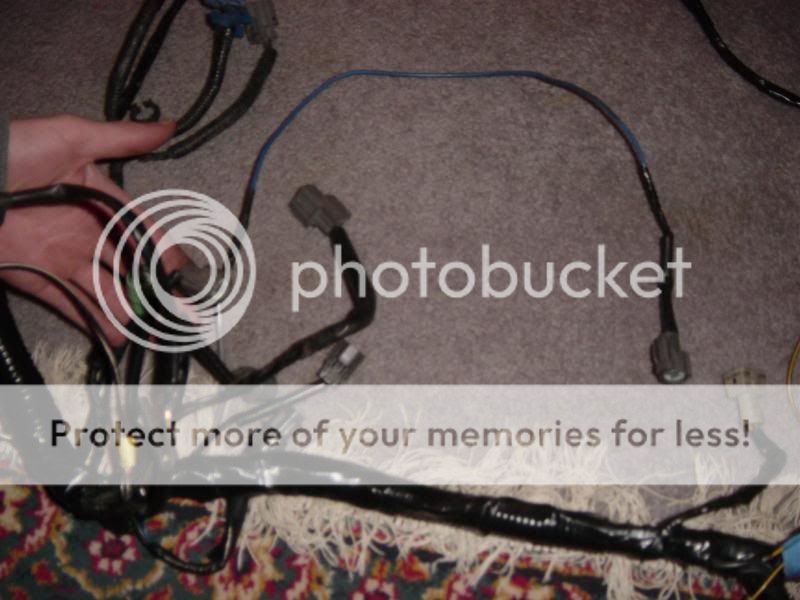

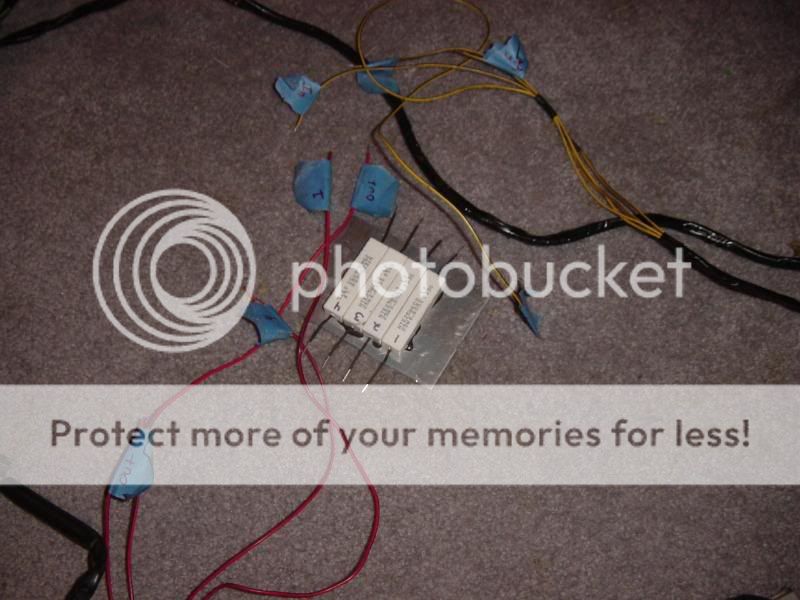

I still have to wire in VTEC into my harness.

The power steering line is different too. I forgot to take a pic today, Ill take one tomorrow.

I will be posting up pics continuously as I do the swap, so hang tight.

01-25-2006, 10:25 AM

Honda North America wont even let their dealrships get Canadian parts, let alone Japanese or UK parts. I am going to have to settle for a DSG custom, which is fine with me.

This thread has been severely pruned because doing this much took long enough. I can answer pretty much any question regarding this job, (and many others).

This information is all from my original thread on Everything-honda.com, which has unfortunately gone under. Another unfortunate event was the passing of imagestation.com;

which is where I had originally hosted all my pics. Some of which were uploaded directly from my camera, and never to my hard drive. So they are lost forever,

I did my best to rehost and replace all the pics I could. I skipped some due to relevancy, others due to their absence.

I hope people find this information useful, its taken me all night to do.

01-24-2006, 10:00 PM

So the motor arrived today and it looks great. Steve at www.hmotorsonline.com hooked it up.

I was first told it was going to be out of a '93, but its actually out of a '95, Im not complaining.

JDM tIgHT yO!!1!1!

So today I took the tranny off and made sure it had the LSD, its did . I also took the pressure plate and clutch disc off to see what condition they were in. Used, obviously, but no bad at all. I took the die grinder with a sanding brush on it to the pressure plate and flywheel.

And the clutch disk still looks good. If my ACT is the same size, its going in the H22 though, no question.

After greasing up the input shaft, throwout bearing, and clutch fork again, I put the tranny back on.

As I was doing so, I say this:

The two lines coming out of the tranny, as I later found out, are for the Rear Wheel Steering. I may use it for a tranny cooler later down the line.

This is the motor mount that is different from the F23 mount. I am going to make a custom one to replace it.

Skunk2 Hooks it up again.

I still have to wire in VTEC into my harness.

The power steering line is different too. I forgot to take a pic today, Ill take one tomorrow.

I will be posting up pics continuously as I do the swap, so hang tight.

01-25-2006, 10:25 AM

Ill take a pic of the f mount tomorrow to show the difference.2kAccord said:Whoa, i dont know how i missed this thread. I didnt realize you were swapping so soon. The H-motor looks sick!

Whats the deal with the motor mount though, I though the f and h blocks were the same??

da_accordian said:about the custom motor mount, I heard you can use the driver side motor mount from an Accord Euro R

Honda North America wont even let their dealrships get Canadian parts, let alone Japanese or UK parts. I am going to have to settle for a DSG custom, which is fine with me.