Hey guys,

My smog/emission test is coming up this summer and i have yet to figure out a remedy for my p0420 code.

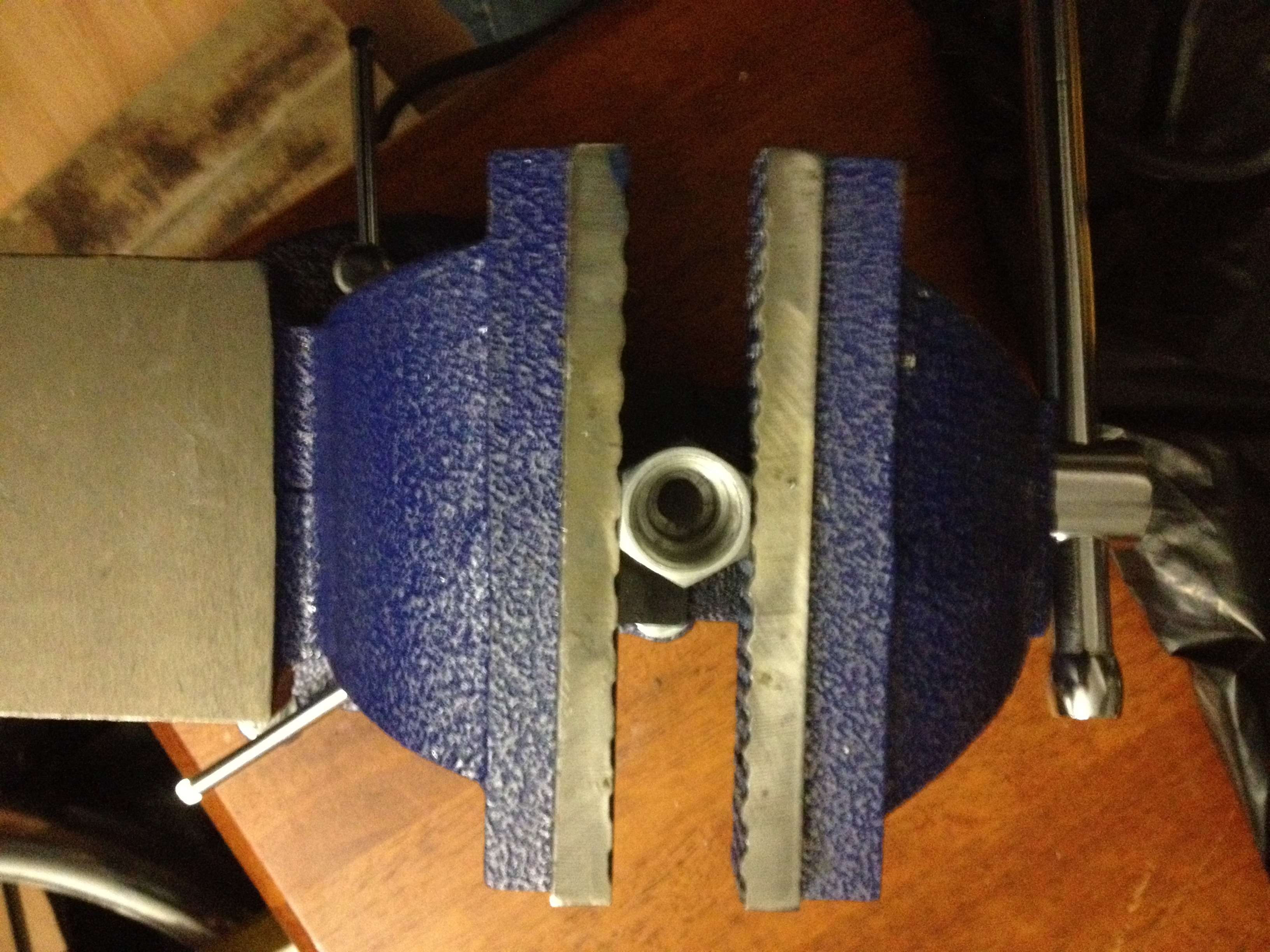

I have read that a cheap fix would be to use the spark plug non fouler BUT the 18mm won't fit on my O2 sensor. It seems to be too short for it to fit

Has anyone found a fix for this?

I was thinking of drilling straight through it to make it fit.

Any thoughts guys?

http://imageshack.com/a/img837/2563/rd8c.jpg

My smog/emission test is coming up this summer and i have yet to figure out a remedy for my p0420 code.

I have read that a cheap fix would be to use the spark plug non fouler BUT the 18mm won't fit on my O2 sensor. It seems to be too short for it to fit

Has anyone found a fix for this?

I was thinking of drilling straight through it to make it fit.

Any thoughts guys?

http://imageshack.com/a/img837/2563/rd8c.jpg

Last edited: