Pulling into the driveway on Tues evening the brake pedal started feeling very soft. I was still able to stop, barely, and when I checked the reservoir it was way down. I looked under the car and saw a fresh stain of a few drops of brake fluid, and when I felt around the plastic rack under the car that protects the lines there was some more up in there. So I've left the car in the garage since then, waiting while I figure out what to do (and for the weather to figure out what it wants to do as well).

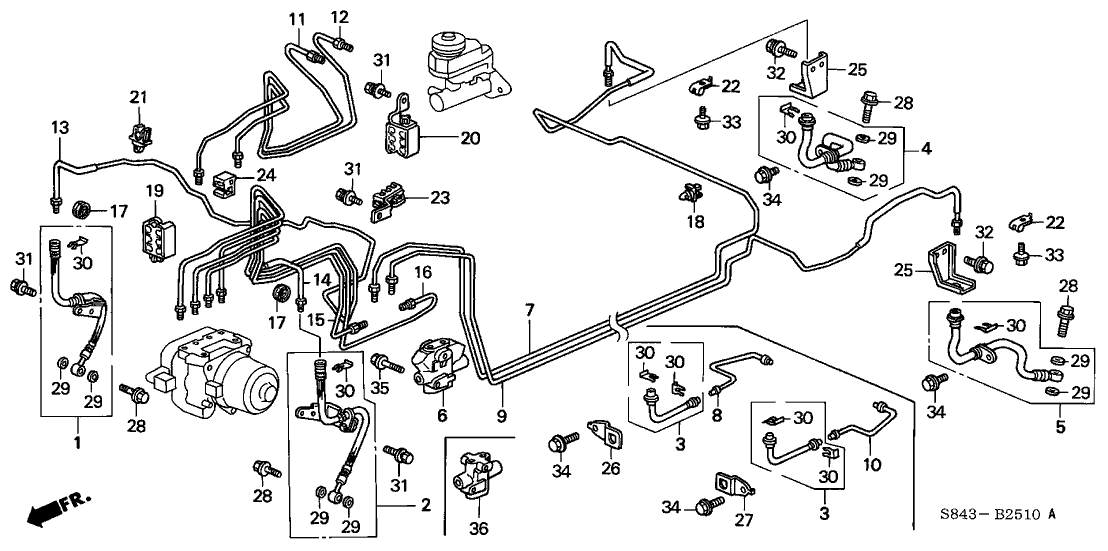

The drops seem to have fallen right below the driver's seat area, right about the break on item 7 or 9 on the HondaPartsNow diagram.

Obviously I need some new brake lines, so with the help of this (link) thread I've figured out a few options:

1. Buy copper/alloy line and rent/buy a flare tool, cutter, and bender to put them in myself

2. Buy a flexible stainless line replacement kit (like this one from Valex Racing)

3. Take it to my mechanic to have him do option 1 for me

Do those stainless lines look any good? It's really tempting to not have to flare or bend any tubing. I've been trying to learn the difference between double flare and bubble flare, since I've read that our cars need a metric bubble flare to seal properly. (Do I understand that correctly?) I think I can handle it as long as I know I'm buying the right size and type of tubing, and getting the correct tool. I've been wanting to do this since I had to take my old car in to the mechanic for the same thing, but I don't want to miss any 'gotchas' when doing something as important as brakes.

Until then the car will be in the garage and I'll be getting rides from my wife or driving her old car, so I'm not in dire need of fixing this right this minute. I'd just like to get prepared and hope for some warmer weather next week to make this snow go away.

snow go away.

The drops seem to have fallen right below the driver's seat area, right about the break on item 7 or 9 on the HondaPartsNow diagram.

Obviously I need some new brake lines, so with the help of this (link) thread I've figured out a few options:

1. Buy copper/alloy line and rent/buy a flare tool, cutter, and bender to put them in myself

2. Buy a flexible stainless line replacement kit (like this one from Valex Racing)

3. Take it to my mechanic to have him do option 1 for me

Do those stainless lines look any good? It's really tempting to not have to flare or bend any tubing. I've been trying to learn the difference between double flare and bubble flare, since I've read that our cars need a metric bubble flare to seal properly. (Do I understand that correctly?) I think I can handle it as long as I know I'm buying the right size and type of tubing, and getting the correct tool. I've been wanting to do this since I had to take my old car in to the mechanic for the same thing, but I don't want to miss any 'gotchas' when doing something as important as brakes.

Until then the car will be in the garage and I'll be getting rides from my wife or driving her old car, so I'm not in dire need of fixing this right this minute. I'd just like to get prepared and hope for some warmer weather next week to make this

snow go away.

snow go away.