Alright guys, I know it’s been quite a while but seriously I have not given up on this project. In fact I’m as determined as I was when I took the wheels off. Money was hella slow for the past year and is getting better. I have to save up a lot to get back to where I was, but parts/tools will be slowly coming in. My main hurdle right now is that I have a job and am too busy to grind on the car. I am working 40-45+ hours every week at my normal job plus I’m helping my wife with her side job. So after all that and having to take care of the house/yard finding time to work on it has been troubling, especially when I still haven’t fully recovered from being in the hospital last November. I feel normal people my age could do what I do and then stay up 2-3 hours extra a night and work on it, but I am dragging and have to rest so that I can focus at work. Also the occasional graduate school class isn’t helping either. I really am trying my hardest and am thinking up new ideas for the build daily.

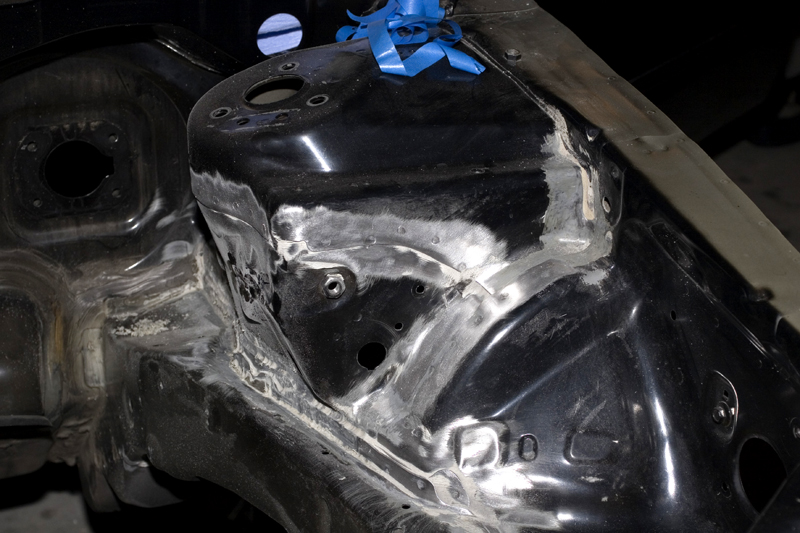

I’m currently working on prepping the stripped chassis for the roll bar, stitch-welding, engine bay shaving. I’m trying to get all the OEM seam sealer cleaned out, but I’m not sure how far I want to go with it because I am not knowledgeable about chassis stuff and need some input on areas to concentrate on. A lot of this is cosmetic, but at the same time I want to expose a few seams where extra strength would be needed and stitch weld where it’s needed. I just kinda figure because I have the car stripped down and the point of this car is for it to be as light as possible it will need extra strength to lessen chassis flex.

I don’t really care to be done anytime soon, I love doing this and the longer it takes the more fun I will have. So if I end up acid dipping the car and stitch welding the whole shebang it wouldn’t hurt my feelings any. In fact if I can find a place that will do it and it feasibly priced I would prefer it.

A lot of you know this already but I thought I should go ahead and state it in here. I plan on continuing the light weight direction of the car with the motor itself and am tossing the whole V6 power plant metaphorically out the window. I would love to see someone do a turbo V6 with a reverse manifold because it would look badass and I know it’s possible, but just because I have an idea doesn’t mean that I am going to put it on this car. The car is not meant to be the fastest or anything like that, it’s meant to be what I consider the best combination of parts in my favorite car. I want everything in the car to be logical and toward a specific direction. There may not even be a radio or anything. I kinda think a turbo v6 will be overkill for the balance of the car in terms of weight and power. Not to mention I prefer the look of a k20 in a 6ga bay any day over a v6. After thinking of every option I could do to the v6, I just still wasn’t happy with what it would be. So for now, I plan on putting a k20 in there. Since I’m kinda far from the point where I buy a motor though, this could still change if I think up something I like more.

True be known, by the time I get to put a motor in. I might be chroming the case of a 100lb brushless motor and using Li-ions as ballast around the car.

Next thing I am doing are the brake lines. I have a friend with a brake line bender and flare tool so I don’t have to buy those. I plan on buying some brake line to practice flaring and bending with. I’m not sure but I may have to invest in a better flare tool than the one my friend has. I want the lines to look OEM but I can’t use the pre-bent lines because I am hiding the lines and need to bend them so they can be hidden various places.

I was also going to make a sunroof plug, but with the level I am gonna do this. I might as well just weld it in. This way there will be no leaks. I still want to learn how to do fiberglass to make my own stuff but I dunno when I’ll have time to do that.

Anyways, tonight I started removing some of the sound deadener and the only pics I have for now to post are of that. Like I said…I wish I could go faster but some other things come first.

Here are some pics of me using the dry ice to freeze the sound deadening and pulling it up.

this is my start at removing the seam sealer just to see what a ***** this is gonna be....OMG...it sucks...but it will take a LOT more work and I will make more headway once i figure out which welder I want to buy and all that...