Hey all. So my wife's 2000 Accord LX, 2.3 ltr, blew a head gasket. Being a handy guy, I decided to tear it down in the garage and take the head to the local machine shop to get it checked out and machined. Everything came apart as planned, took it to the shop and decided to have them do a valve job on it as well as long as I had it apart.

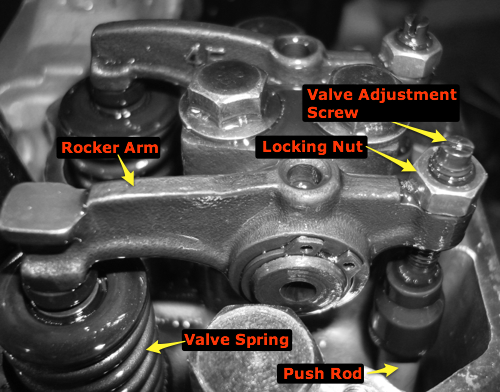

A couple days later the head comes back checked out with a fresh set of valves and looking brand new. I begin putting everything back together, all goes smooth.... Until I get the valve assembly back in and try adjusting the valves.

On every cylinder both valves on the exhaust side and the intake valve on the passenger side adjust fine. But on every cylinder, of the two intake valves, the one on the driver side is adjusted all the way out and I still can't get the feeler gauge in. If I press down on the end opposite the adjuster I can raise the valve enough to adjust it properly, but it feels like there is some sort of tension keeping that valve down on each cylinder. I have been doing a lot of this today trying to puzzle my way through this

While I have done the valves on other vehicles, this is the first time I have done it on an accord. Any advice??? I am at a complete loss and can't go any father putting it together until this gets fixed. My wife and I are sharing one vehicle. This sucks!! I would like to get this car running ASAP so we can stop sharing one vehicle.

thanks in advance. If I am leaving out something critical, let me know and i will get the info.

A couple days later the head comes back checked out with a fresh set of valves and looking brand new. I begin putting everything back together, all goes smooth.... Until I get the valve assembly back in and try adjusting the valves.

On every cylinder both valves on the exhaust side and the intake valve on the passenger side adjust fine. But on every cylinder, of the two intake valves, the one on the driver side is adjusted all the way out and I still can't get the feeler gauge in. If I press down on the end opposite the adjuster I can raise the valve enough to adjust it properly, but it feels like there is some sort of tension keeping that valve down on each cylinder. I have been doing a lot of this today trying to puzzle my way through this

While I have done the valves on other vehicles, this is the first time I have done it on an accord. Any advice??? I am at a complete loss and can't go any father putting it together until this gets fixed. My wife and I are sharing one vehicle. This sucks!! I would like to get this car running ASAP so we can stop sharing one vehicle.

thanks in advance. If I am leaving out something critical, let me know and i will get the info.

Last edited: