BadgerType

Resident ***hole

DIY: Automatic to Manual Transmission Swap

Warning: This DIY is a Step by Step demonstration on how to convert your car from automatic to manual. IT IS NOT COMPLETE YET!!!!! This will make your car drivable, just no speedo, vtec and reverse lights. I am not you and therefore not responsible for any damages to you or your car.

Difficulty: 10 outta 10

Time: 4+ days

CAUTION: THIS IS NOT 100% GUIDE!!! My car is not yours so i may have removed some stuff before this swap. If you have any aftermarket stuff tht is not listed, you must remove it just like it was installed. There maybe some other things that i have overlooked or not covered. Use your best judgment in this situation. Please make sure you are willing to deal with the mechanical and electrical parts of the car. DO NOT BLAME ME OR THIS WRITE UP IF YOUR SWAP DOES NOT WORK. IF YOU HAVE ANY SPECIFIC QUESTIONS, please pm me and ill do my best to help you out

I recommend that you use some sort of system to keep all parts and bolts in order. i used the baggy system and worked great

TOOLS:

Metric wrenches(8mm-19mm)

Metric Sockets(8mm-19mm)

3/8 socket wrench

flathead screwdriver

phillips head screwdriver

36mm Axle socket

pliers

needle nose pliers

crescent wrench

wire snips

wire stripper

Solder iron

electrical tape

dremel

tungsten drill bit

multimeter

Ball joint fork

Glasses

Gloves

2 Jacks

2 Jack stands

hammer

Breaker Bar

3'+ cheater bar

baseball bat

1. Disconnect the battery and remove it outside of the car. remove the tray beneath it as well

2. BEFORE JACKING UP THE CAR, take a 36mm socket and loosen the axlenuts on both sides. First you must hammer out the notch on the axle nut itself. use a small flathead and hammer to round out the nut. then break loose the axle nuts. it will take a good deal of force, one of mine had to have 2 people push to break it loose. DO NOT REMOVE YET

3. Jack up your car and place the car on jackstands. MAKE SURE YOUR EBRAKE IS ENGAGED!

4. Remove the lugnuts on both front tires. remove tires and set aside

5. Go underneath the car and remove all under engine plastic. i cant tell ya how since mine was gone a long time ago, lol

6. drain the coolant via drain cock and drain the auto trans fluid via 3/8 ratchet nut on transmission. PROPERLY REMOVE AND DISPOSE OF FLUIDS! (I also did my oil as well, since i was down there)

7. While the fluids are draining, go back on top and remove everything that is gonna get in the way (Intake, top radiator hose, bottom radiator hose, radiator overflow tank) The hoses can be undone with a set of pliers.

8. now onto the radiator, remove the 2 10mm bolts that hold the radiator down. before you remove it from the car, there are 2 more hoses on the bottom of the radiator that go to the tranny. unclip with a set of pliers.

9. unclip the plugs on the fans, i believe there are 3 of them. now you can remove the radiator. MAKE SURE you have the 2 little rubber feet the radiator sits on as well. Set aside

10. now go back to the axles nuts that you broke loose earlier. remove axle nut completely with 36mm socket.

11. remove the bolt the connect the strut to the spindle. you will need 2 17mm socket/wrenches to remove the bolt. then loosen the bolt near the strut itself. remove this part out of the way

12. look on the underside of each spindle and you will see a castle nut with a cotter pin in it. straighten out the cotter pin then remove the cotter pin with a needle nose pliers. with the cotter pin removed take off the castle nut with a 17mm socket.

13. with the castle nuts removed, you can pop the ball joints. now don't bust open the ball joints cause that would be bad, but you should wedge the balljoint fork between the ball joint and the lower control arm. it helps if you slowly jack up the rotor and gently hammer the fork to pop up the ball joint.

14. hammer the axles out of the spindles. then take the ball joint fork and pop out the axles out of the transmission. save the passenger side axle, you will reuse it.

15. now the radius rods, there are 2 14mm bolts on the lower control arms. make sure not to twist the actual rods or you will have a fun time trying to figure out how it was situated

16. now position a 2x4 under oil pan and place a jack under the oil pan. you don't want to damage the the actual oil pan.

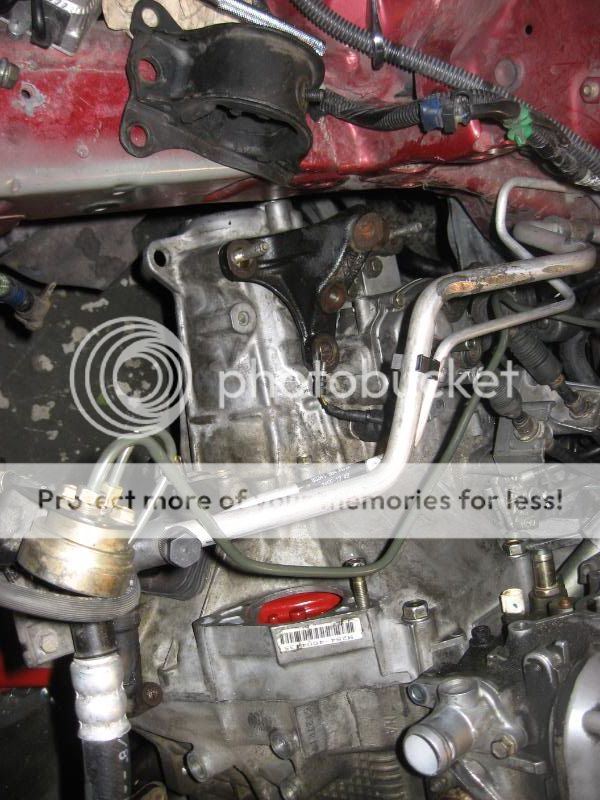

17. look at the front motor mount, remove the 19mm bolt through the mount. unbolt the 3 17mm bolts for tranny mount on the engine itself. removal make putting the tranny on later.

18. there are 3 17mm bolts on each side that hold up the engine subframe as well as 2 bolts up front right next to radius rods. once these bolts are removed, the subframe will come down. set aside

19. while down there, look back and find the heat shield over the exhaust pipe. remove the 2 10mm bolts and 2 10mm nuts that hold up the shield. this will help ya later with running the shift cables later

20. head back up top and find your starter. disconnect the plug going to the starter and remove the 2 17mm bolts on the starter.

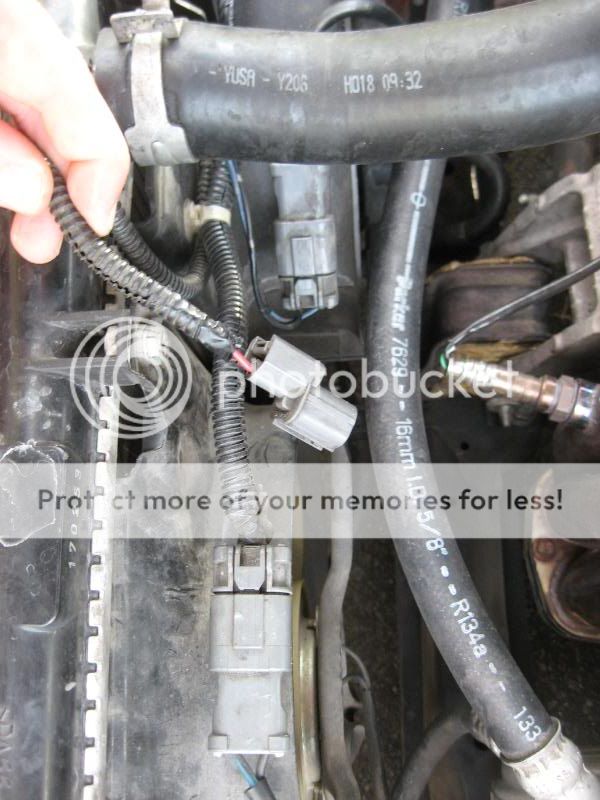

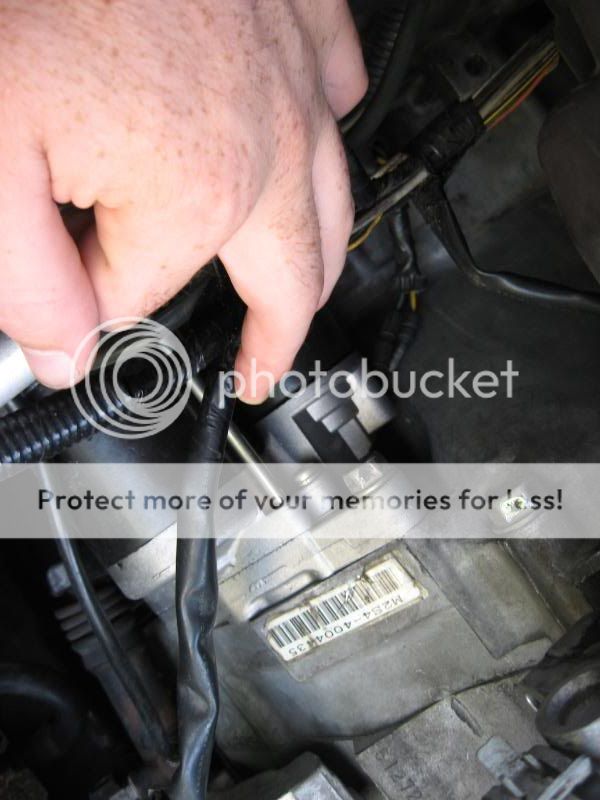

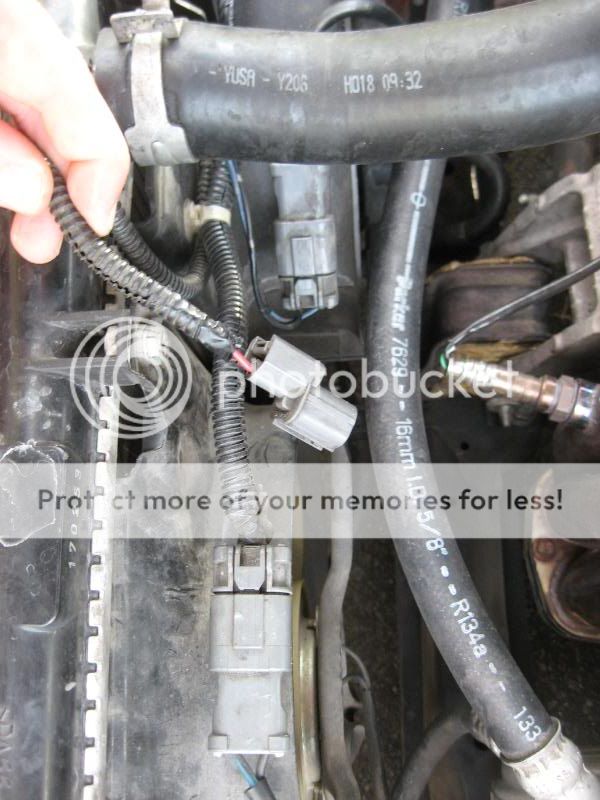

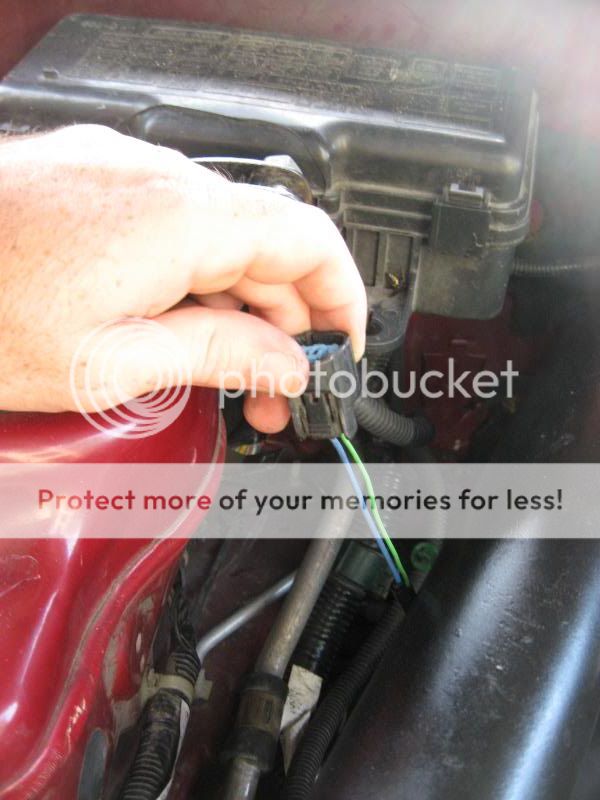

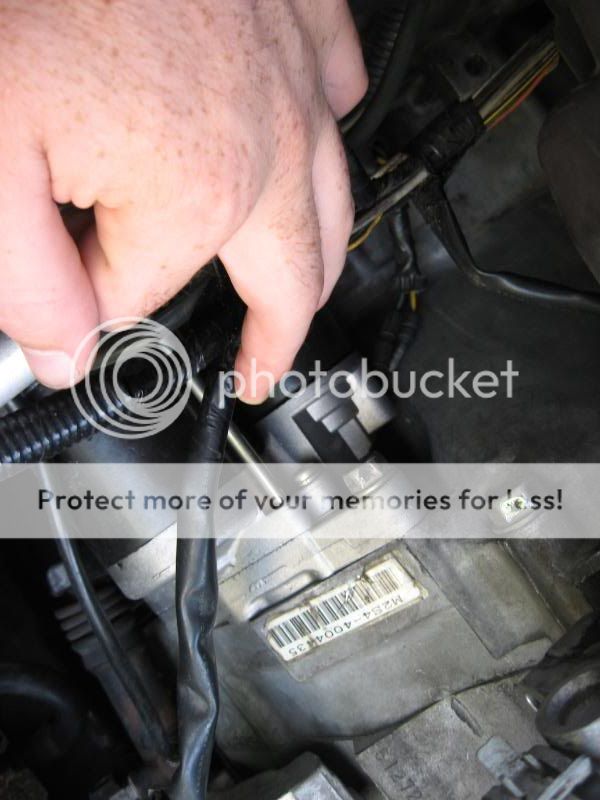

21. disconnect all plugs on the transmission. you can snip them off if you want to now or later. only the big master plug and the blue/green plug will be needed later

22. disconnect the plug going to the distributor. remove the 2 12mm bolts on the distributor. removing the distributor will allow an easier tranny removal

23. back under the car again, remove the 4 bolt that cover the bottom part of the tranny, aka dust shield. you can now see your flex plate and torque converter

24. remove all 8 14mm torque converter bolts. to remove all of them, you must twist the actual flexplate to see and access them all. it helped me that i wedged a wrench on the crank pulley bolt to stop the plate from moving

25. if you want to remove the actual shift cable now, you can. i choose to leave it on until the tranny was off the car. to do so, remove the cover over the shift cable. from there you remove the safety clip on the bolt and slide off the cable.

26. time for the rear mount, its a weird looking mount our automatics are. you can reuse the mount fine, no drilling no modding. remove the 4 bolts on the mount. MAKE SURE your jack is holding up the oil pan still.

27. now place a second jack with another 2x4 under the tranny. make sure its just holding it up, no more

28. remove the bolt going through the tranny side mount. then the 3 17mm bolts for the tranny mount. you will reuse this. MAKE SURE YOU HAVE BOTH JACKS WORKING AT THE RIGHT HEIGHT. ONLY 1 MOUNT IS HOLDING UP THE ENGINE. IF NOT AND THAT WOULD BE VERY BAD.

29. remove all but the top 2 17mm bolts the hold the tranny to the engine block. there are 2 that go from the block to the tranny on the backside of the tranny as well.

30. when ready, remove the last two top bolts. slowly lower the tranny jack and oilpan jack to tilt the tranny downward. this is needed to help separate the tranny from the block.

31. gently start prying the tranny off at the top with a flathead screwdriver. if it doesn't start prying off, STOP and make sure you removed all the tranny bolts.

32. once the torque converter is separated well enough from the flex plate, start lowering the tranny. IT WEIGHS ALOT SO BE CAREFUL!! if the mount on the tranny is interfering, loosen it up to make room.

33. Want proof of how heavy it the tranny is? try moving the transmission off the jack. it is heavy. be careful of the torque converter. behind it is alot of tranny fluid than can leak out

WOOT!!!! YOU DID IT! take a break, drink a beer, clean up. next is the interior

34. there is alot of interior pieces to remove. start out by removing the driver side seat. 4 14mm bolts hold the seat down and 2 plugs. once unbolted, remove seat carefully from car and put it out of the way, or do what i did and used it as my lounging chair during the swap, lol

35. next are both kickpanels(pull off, but be careful) and fuse covers as well as the glove box. glove box comes off by opening up the glove box and removing 2 screws by the latch and 2 more screws beneath the black tabs. once done, the glove box will come out

36. finale the whole center console by starting with the cup holder, the black acc outlet, than the main center piece

37. once removed, start unplugging the auto shifter. then remove the 4 12mm bolts that hold down the shifter.

38. remove the auto shift cable by twisting it off the shifter. remove shifter and remove cable including the rubber piece

39. run the new shifter cables through the open hole. MAKE SURE that the rubber is snuggly over the hole. otherwise it may come loose and allow the outside weather in

40. install your new 5spd shifter in. bolt down with same 4 12mm bolts.

41. slide on the 2 shifter onto the shifter. bolt on with oem parts.

42. install your shift boot and shift knob to make it look official, lol

43. install the center console back together

44. pull back the carpet on the driver and passenger side to reveal the ECU. remove the 2 10mm bolts that hold down the ECU. you will need to access ths later

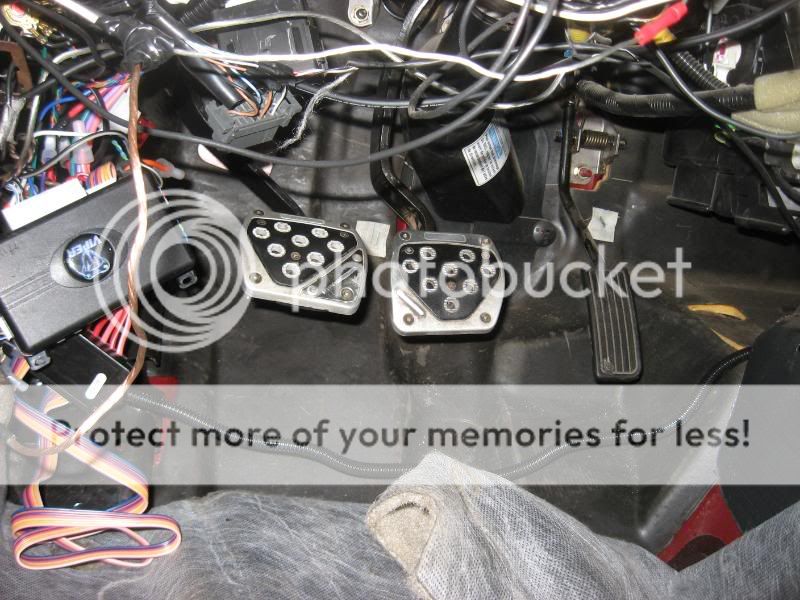

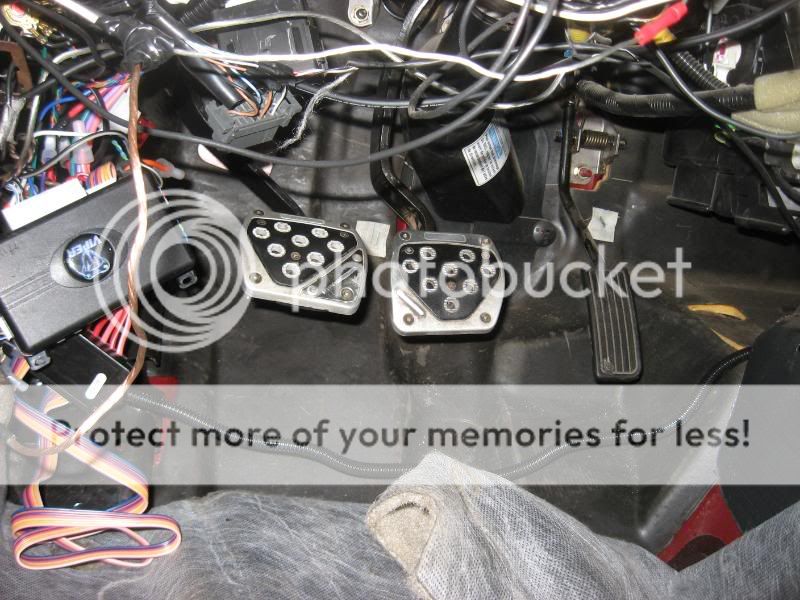

45. now i cheated and used the automatic brake pedal and modified it to work. if you want to follow my DIY, skip to the next step.

46. DO AT YOUR OWN RISK! remove the padding on the brake pedal. take a manual brake pedal pad and center it on the brake pedal.

47. using a blade or other sharp tool, trace out the general shape of the pad. use the tungsten bit or cutting wheel to cut off the excess pieces. looks crooked but aint

48. using a sanding bit, sand down the rough edges. once sanded down, place new pad over the newly cut pedal and test it out to make sure it feels right

49. the clutch pedal is a fun little project. start by cutting out the 3 holes on the firewall with your tungsten drill bit on your dremel. trust me, i tried other bits but this is like cutting through butter with a hot knife

50. test fit the master cylinder in the holes, if it don't fit, make the necessary adjustments

51. install the master cylinder from the engine bay going in.

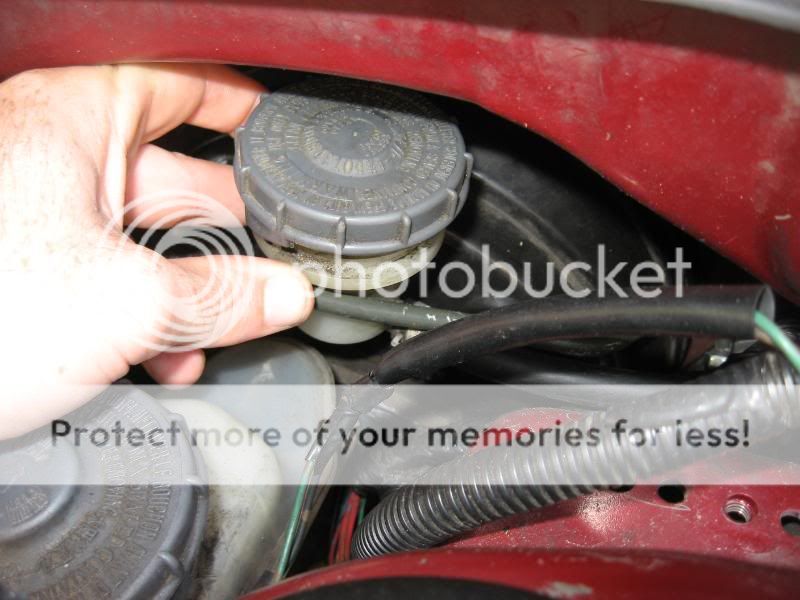

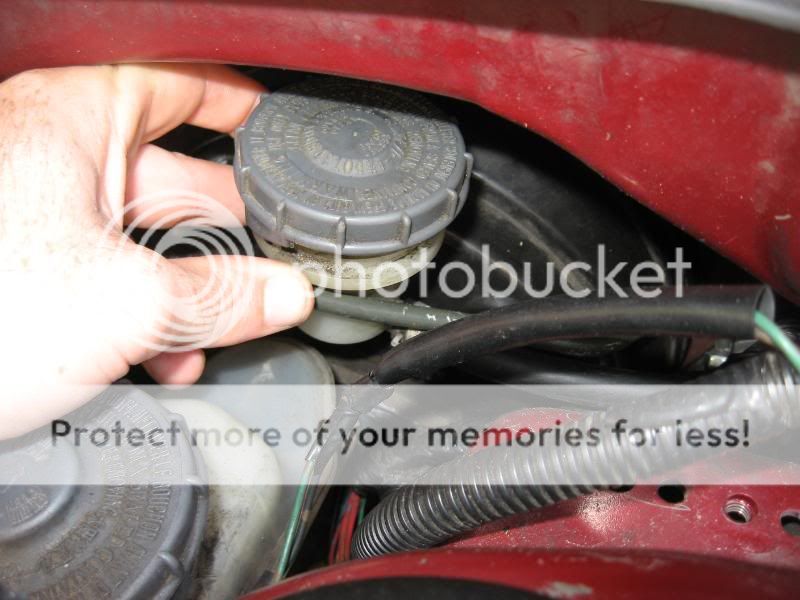

52. MAKE SURE that you install some sort of spacer between the firewall and pedal on the studs. if u fail to do so, your clutch will be slightly pressed in all the time and would lead to premature clutch failure. i used 2 thick washers and they seem to do the job

53. next install the pedal onto the master cylinder. secure with 2 nuts. then hook up the plunger to the pedal via oem parts.

small mini break to take pics of your new shifter, lol

54. breaks over. tme to get dirty again. start by making sure your tranny of choice, f23, h23, h22 or f22 (i choose the h23) has the slave cylinder attached on. everyone says you must use the f23 slave cylinder, but i was able to cheat the h23 on there. the reason why they use the f23, is due to clearance with the front mount

55. i recommend breaking loose the manual drain bolt and adding some fluid to the tranny now. not alot but just enough to lubricate the inner gears.

56. hop under the car and break off the 8 14mm 12pt flex plate bolts off the block. use the same socket wedging you used to break off the torque converter bolts. remove flex plate

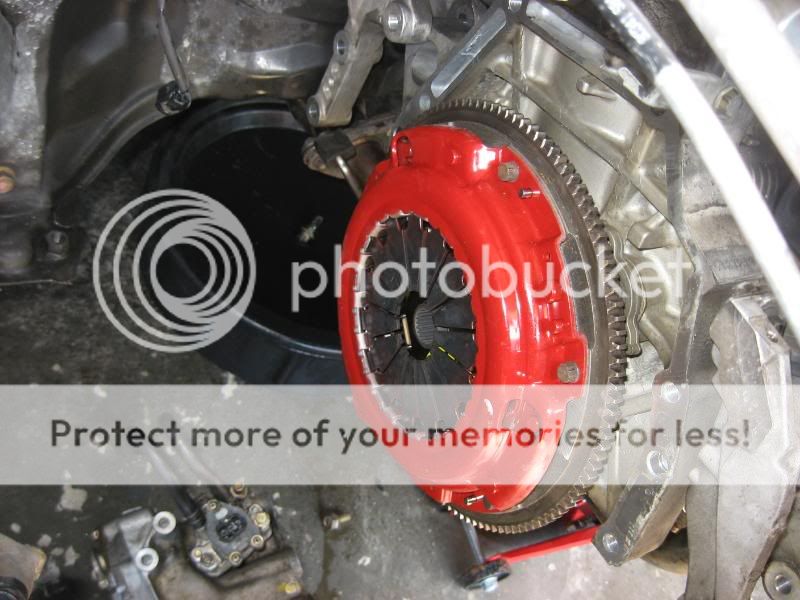

57. now install your flywheel of choice. i just used an oem one but what ever you use, make sure it has a clean, smooth surface. attach by using 8 14mm 12pt

flywheel bolts. tighten down in a crisscross manner. clean the surface the flywheel with brake cleaner. NO!!!!

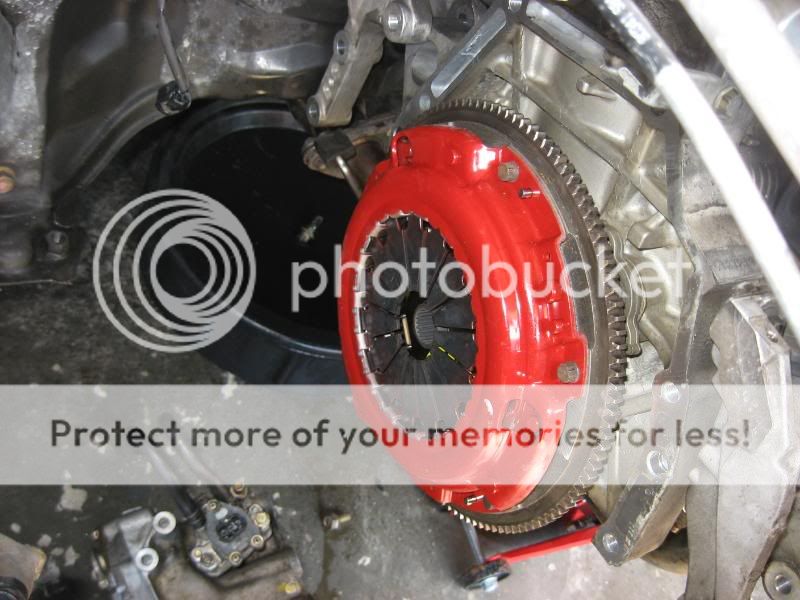

58. the clutch kit should be up to you. i got a good stg 1 clutch for a good price. install the clutch onto the flywheel via clutch instructions. tighten down the 10mm 12pt bolts in a crisscross manner.

59. back to the tranny, install a new throw out bearing onto the shift fork. position the tranny to be lifted up. double check to see if you have the vss and reverse switch installed

60. get a friend to go under the car and hold the tranny up while you thread a tranny bolt into the block. MAKE SURE that you don't mess with the fins on the clutch. place a jack under the tranny for support to hold up the tranny. you may have to wiggle or kick the tranny onto the engine.

61. start threading the bolts by hand into the block.

62. once you have the majority threaded in, start tightening them down in a crisscross like pattern. MAKE SURE that the tranny goes on straight and not crooked

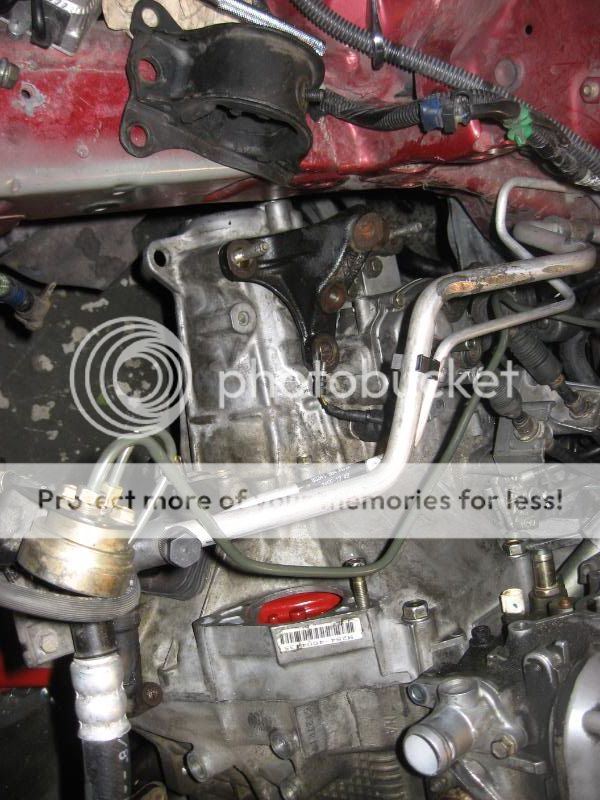

63. install the tranny mount onto the tranny and onto the wall

64. now screw in the bolts for the rear mount. you may have to jack up or down the tranny jack to line up the holes

65. back to the subframe, make sure the front engine mount is on both the engine and the subframe. do not tighten all the way yet

66. lift up the subframe and start attaching the bolts back onto the car, 6 on the backside, 2 in the front and 4 on the lower control arms. tighten all of them up

67. rebolt the front mount together. then tighten down all the bolts for the front mounts

68. now you can remove both jacks. Take another break. the heavy stuff is done.

69. head under the car again, find the shift cables and route them up to the tranny. to do so correctly, have them go up the firewall, over the rear mount but under the intake manifold.

70. install the shift cable holder onto the tranny via the 3 bolts. install the shifter cables onto the holder via 2 c-clips.

71. slide the ends of the shifter cables onto the shifter forks. MAKE SURE you use some sort of washer and cotter pin if not OEM parts. all you need is to shift on the road and the cables or bushing to pop off

72. install the heat shield again with the 2 bolts and 2 nuts

73. install the dustcover on the underside of the tranny. there may be an issue with one of the bolts not lining up, but the rest should hold it in fine

74. grab a 3/8 ratchet and break loose the drain bolt on the manual tranny again. using a funnel and 1/4" tubing, fill the manual tranny with your choice of tranny fluid. i first used honda MTF but am switching to 50w synthetic for slower shifting. fill it to the point where it overflows a lttle. tighten down nut

75. the intermediate shaft need to be installed onto the block before your new driverside axle can be put in. just slide the shaft all the way into the tranny and match the bolt holes up and install the bolts.

76. now the new driverside axle, first place the axle over the horseshoe strut piece. then slide the axle through the spindle. gently force it all the way into the spindle.

77. now slide the axle into the intermediate shaft. MAKE SURE that it is fully in the intermediate shaft. to do so, take the fat end of a baseball bat and gently hammer it all the way in while turning the axle. there can not be almost any gap. gaps equal popped out axles.

78. CAREFULLY place the spindle ont the lower control arm. if you break the ball joint, it will need to be replaced. tighten it down with the castle nut. line up the hole with the castle nut and slide the cotter pin through. it will be a pain to do, but must be done.

79. take the axle nut and tighten down hand tight. DONT PUNCH THE TAB YET!

80. go to the passenger side and follow the same steps.

81. install any splash shields you took off

82. now head up top and start putting stuff back on. reinstall the distributor with 2 bolts and plug it in

83. get a new starter that matches your year and tranny. MAKE SURE the o-ring terminal is on good and tight and that little plug is connected as well

84. break out the tangle web of line tht is you clutch fluid line. screw in one end to the master cylinder. its a pain to get on but it will go on. get it good and tight.

85. run the lines behind the intake manifold and up to the slave cylinder. screw the other end to the slave cylinder.

86. go back to the master cylinder and hook up the clutch fluid reservoir. if you want to attach it to the firewall go ahead, but mine is just sitting there upright

87. take a look at the radiator. you will see 2 tubes coming out of the bottom of the radiator. these went to your old auto tranny and are not needed anymore. make a loop out of one of the tubes.

88. place the radiator back in. MAKE SURE that the rubber feet are sitting in the seats. attach the top of the radiator to the frame with the 2 10mm bolts

89. install the bottom radiator hose then the top radiator hose. make sure the clamps are on good and tight

90. attach the overflow tank on the radiator

91. time to add some coolant to the radiator. fill it up and add some to the overflow. you may have to add some LATER after you have driven the car some

92. bleeding the clutch is fairly easy. bleeding brand new clutch lines aint. to prime your new lines you will need to buy an actual brake bleeding tool. i made my own out of a cheap bilge pump. take a some generic brake fluid and poor some into the clutch reservoir, leave the cap open. open the 8mm bleed screw with a wrench and place the pump on the bleed screw and start pumping the air out. but be careful that the reservoir doesn't get too low and you start pumping air in the line. once it is primed, close the screw and remove the pump.

93. i recommend you bleed the clutch the right way to make sure there is no air in the line. go to the slave cylinder and find the bleed screw again. place wrench on screw then attach a vacumm hose to open bleed screw leading to a cup of brake fluid, make sure the line is in the fluid, not out of it. add fluid to reservoir, then go to the inside and follow this procedure, clutch pedal pushed in > close bleed screw > lift up clutch pedal > open bleed screw. follow these steps a few time to make sure all the air is out. close screw and check fluid level in reservoir then cover.

94. wait to install the intake and battery till we are done with the wiring. clean up and take your last break of this project hopefully.

NOTE: ALL WIRING MUST BE SOLDERED TOGETHER!!! FAILURE TO DO SO WILL CAUSE YOUR CAR NOT TO WORK CORRECTLY!

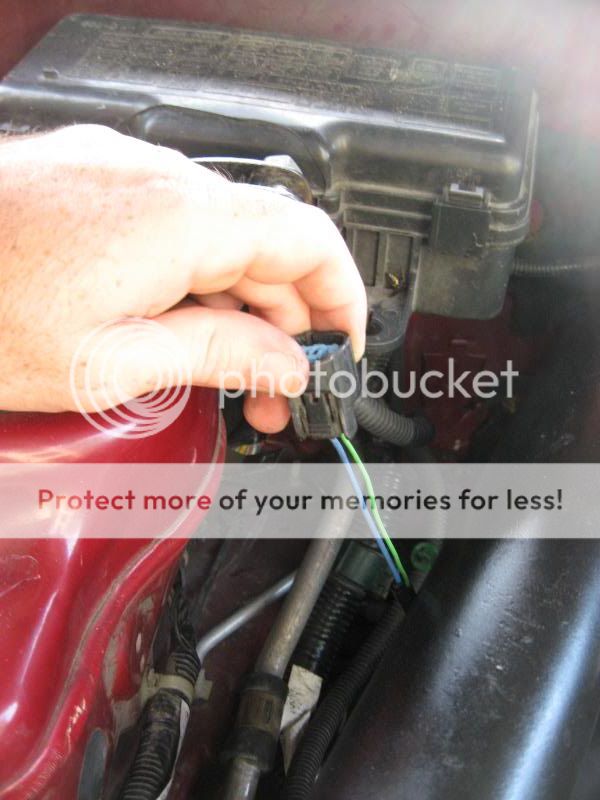

95. the easiest thing to do as far as wiring is to locate the big tranny plug in the engine bay. find the grey and red wire on the plug. strip and solder these 2 wires together. wrap with electrical tape

96. test car to see if car turns over. if it does, CONGRATS......... YOU JUST DID IT

_____________________________________________________________________________

VSS Wiring

This is a simple fix to make the vss/vtec work. if you want to edit this to make it work better, have at it.

lets use this pin diagram:

http://www.driveaccord.net/forums/at...5&d=1111724327

depin the #10 on connector D and install onto 23 on connector C. depinning is a ***** but it must be done for your sake. as far as the vss, i cant confirm wire colors, but when you are looking at the plug, with the clip part on top, the wiring is as follows... ground / power / signal.

now the speedo has to be tee'd off. the auto got an input from the vss to the ecu the sent another signal to the speedo. somewhere along your vss signal line, splice the wire with the blu/wht wire running to the back of your speedo. the other end, not connected to the cluster, is on the pass side behind the fuses.

I CAN NOT PROVIDE WIRING DETAILS ON MY CAR. SINCE I SWAPPED TO OBD-I, MOST OF THE WIRING I DID WILL NOT WORK WITH YOUR CAR. PLEASE USE OTHER WIRING DIAGRAMS FOUND ON THIS THREAD.

thanx to turbowa, s.cali alan, drift, stinker504

DO NOT REPOST WITHOUT PERMISSION

Thanks for lookin

Warning: This DIY is a Step by Step demonstration on how to convert your car from automatic to manual. IT IS NOT COMPLETE YET!!!!! This will make your car drivable, just no speedo, vtec and reverse lights. I am not you and therefore not responsible for any damages to you or your car.

Difficulty: 10 outta 10

Time: 4+ days

CAUTION: THIS IS NOT 100% GUIDE!!! My car is not yours so i may have removed some stuff before this swap. If you have any aftermarket stuff tht is not listed, you must remove it just like it was installed. There maybe some other things that i have overlooked or not covered. Use your best judgment in this situation. Please make sure you are willing to deal with the mechanical and electrical parts of the car. DO NOT BLAME ME OR THIS WRITE UP IF YOUR SWAP DOES NOT WORK. IF YOU HAVE ANY SPECIFIC QUESTIONS, please pm me and ill do my best to help you out

I recommend that you use some sort of system to keep all parts and bolts in order. i used the baggy system and worked great

TOOLS:

Metric wrenches(8mm-19mm)

Metric Sockets(8mm-19mm)

3/8 socket wrench

flathead screwdriver

phillips head screwdriver

36mm Axle socket

pliers

needle nose pliers

crescent wrench

wire snips

wire stripper

Solder iron

electrical tape

dremel

tungsten drill bit

multimeter

Ball joint fork

Glasses

Gloves

2 Jacks

2 Jack stands

hammer

Breaker Bar

3'+ cheater bar

baseball bat

1. Disconnect the battery and remove it outside of the car. remove the tray beneath it as well

2. BEFORE JACKING UP THE CAR, take a 36mm socket and loosen the axlenuts on both sides. First you must hammer out the notch on the axle nut itself. use a small flathead and hammer to round out the nut. then break loose the axle nuts. it will take a good deal of force, one of mine had to have 2 people push to break it loose. DO NOT REMOVE YET

3. Jack up your car and place the car on jackstands. MAKE SURE YOUR EBRAKE IS ENGAGED!

4. Remove the lugnuts on both front tires. remove tires and set aside

5. Go underneath the car and remove all under engine plastic. i cant tell ya how since mine was gone a long time ago, lol

6. drain the coolant via drain cock and drain the auto trans fluid via 3/8 ratchet nut on transmission. PROPERLY REMOVE AND DISPOSE OF FLUIDS! (I also did my oil as well, since i was down there)

7. While the fluids are draining, go back on top and remove everything that is gonna get in the way (Intake, top radiator hose, bottom radiator hose, radiator overflow tank) The hoses can be undone with a set of pliers.

8. now onto the radiator, remove the 2 10mm bolts that hold the radiator down. before you remove it from the car, there are 2 more hoses on the bottom of the radiator that go to the tranny. unclip with a set of pliers.

9. unclip the plugs on the fans, i believe there are 3 of them. now you can remove the radiator. MAKE SURE you have the 2 little rubber feet the radiator sits on as well. Set aside

10. now go back to the axles nuts that you broke loose earlier. remove axle nut completely with 36mm socket.

11. remove the bolt the connect the strut to the spindle. you will need 2 17mm socket/wrenches to remove the bolt. then loosen the bolt near the strut itself. remove this part out of the way

12. look on the underside of each spindle and you will see a castle nut with a cotter pin in it. straighten out the cotter pin then remove the cotter pin with a needle nose pliers. with the cotter pin removed take off the castle nut with a 17mm socket.

13. with the castle nuts removed, you can pop the ball joints. now don't bust open the ball joints cause that would be bad, but you should wedge the balljoint fork between the ball joint and the lower control arm. it helps if you slowly jack up the rotor and gently hammer the fork to pop up the ball joint.

14. hammer the axles out of the spindles. then take the ball joint fork and pop out the axles out of the transmission. save the passenger side axle, you will reuse it.

15. now the radius rods, there are 2 14mm bolts on the lower control arms. make sure not to twist the actual rods or you will have a fun time trying to figure out how it was situated

16. now position a 2x4 under oil pan and place a jack under the oil pan. you don't want to damage the the actual oil pan.

17. look at the front motor mount, remove the 19mm bolt through the mount. unbolt the 3 17mm bolts for tranny mount on the engine itself. removal make putting the tranny on later.

18. there are 3 17mm bolts on each side that hold up the engine subframe as well as 2 bolts up front right next to radius rods. once these bolts are removed, the subframe will come down. set aside

19. while down there, look back and find the heat shield over the exhaust pipe. remove the 2 10mm bolts and 2 10mm nuts that hold up the shield. this will help ya later with running the shift cables later

20. head back up top and find your starter. disconnect the plug going to the starter and remove the 2 17mm bolts on the starter.

21. disconnect all plugs on the transmission. you can snip them off if you want to now or later. only the big master plug and the blue/green plug will be needed later

22. disconnect the plug going to the distributor. remove the 2 12mm bolts on the distributor. removing the distributor will allow an easier tranny removal

23. back under the car again, remove the 4 bolt that cover the bottom part of the tranny, aka dust shield. you can now see your flex plate and torque converter

24. remove all 8 14mm torque converter bolts. to remove all of them, you must twist the actual flexplate to see and access them all. it helped me that i wedged a wrench on the crank pulley bolt to stop the plate from moving

25. if you want to remove the actual shift cable now, you can. i choose to leave it on until the tranny was off the car. to do so, remove the cover over the shift cable. from there you remove the safety clip on the bolt and slide off the cable.

26. time for the rear mount, its a weird looking mount our automatics are. you can reuse the mount fine, no drilling no modding. remove the 4 bolts on the mount. MAKE SURE your jack is holding up the oil pan still.

27. now place a second jack with another 2x4 under the tranny. make sure its just holding it up, no more

28. remove the bolt going through the tranny side mount. then the 3 17mm bolts for the tranny mount. you will reuse this. MAKE SURE YOU HAVE BOTH JACKS WORKING AT THE RIGHT HEIGHT. ONLY 1 MOUNT IS HOLDING UP THE ENGINE. IF NOT AND THAT WOULD BE VERY BAD.

29. remove all but the top 2 17mm bolts the hold the tranny to the engine block. there are 2 that go from the block to the tranny on the backside of the tranny as well.

30. when ready, remove the last two top bolts. slowly lower the tranny jack and oilpan jack to tilt the tranny downward. this is needed to help separate the tranny from the block.

31. gently start prying the tranny off at the top with a flathead screwdriver. if it doesn't start prying off, STOP and make sure you removed all the tranny bolts.

32. once the torque converter is separated well enough from the flex plate, start lowering the tranny. IT WEIGHS ALOT SO BE CAREFUL!! if the mount on the tranny is interfering, loosen it up to make room.

33. Want proof of how heavy it the tranny is? try moving the transmission off the jack. it is heavy. be careful of the torque converter. behind it is alot of tranny fluid than can leak out

WOOT!!!! YOU DID IT! take a break, drink a beer, clean up. next is the interior

34. there is alot of interior pieces to remove. start out by removing the driver side seat. 4 14mm bolts hold the seat down and 2 plugs. once unbolted, remove seat carefully from car and put it out of the way, or do what i did and used it as my lounging chair during the swap, lol

35. next are both kickpanels(pull off, but be careful) and fuse covers as well as the glove box. glove box comes off by opening up the glove box and removing 2 screws by the latch and 2 more screws beneath the black tabs. once done, the glove box will come out

36. finale the whole center console by starting with the cup holder, the black acc outlet, than the main center piece

37. once removed, start unplugging the auto shifter. then remove the 4 12mm bolts that hold down the shifter.

38. remove the auto shift cable by twisting it off the shifter. remove shifter and remove cable including the rubber piece

39. run the new shifter cables through the open hole. MAKE SURE that the rubber is snuggly over the hole. otherwise it may come loose and allow the outside weather in

40. install your new 5spd shifter in. bolt down with same 4 12mm bolts.

41. slide on the 2 shifter onto the shifter. bolt on with oem parts.

42. install your shift boot and shift knob to make it look official, lol

43. install the center console back together

44. pull back the carpet on the driver and passenger side to reveal the ECU. remove the 2 10mm bolts that hold down the ECU. you will need to access ths later

45. now i cheated and used the automatic brake pedal and modified it to work. if you want to follow my DIY, skip to the next step.

46. DO AT YOUR OWN RISK! remove the padding on the brake pedal. take a manual brake pedal pad and center it on the brake pedal.

47. using a blade or other sharp tool, trace out the general shape of the pad. use the tungsten bit or cutting wheel to cut off the excess pieces. looks crooked but aint

48. using a sanding bit, sand down the rough edges. once sanded down, place new pad over the newly cut pedal and test it out to make sure it feels right

49. the clutch pedal is a fun little project. start by cutting out the 3 holes on the firewall with your tungsten drill bit on your dremel. trust me, i tried other bits but this is like cutting through butter with a hot knife

50. test fit the master cylinder in the holes, if it don't fit, make the necessary adjustments

51. install the master cylinder from the engine bay going in.

52. MAKE SURE that you install some sort of spacer between the firewall and pedal on the studs. if u fail to do so, your clutch will be slightly pressed in all the time and would lead to premature clutch failure. i used 2 thick washers and they seem to do the job

53. next install the pedal onto the master cylinder. secure with 2 nuts. then hook up the plunger to the pedal via oem parts.

small mini break to take pics of your new shifter, lol

54. breaks over. tme to get dirty again. start by making sure your tranny of choice, f23, h23, h22 or f22 (i choose the h23) has the slave cylinder attached on. everyone says you must use the f23 slave cylinder, but i was able to cheat the h23 on there. the reason why they use the f23, is due to clearance with the front mount

55. i recommend breaking loose the manual drain bolt and adding some fluid to the tranny now. not alot but just enough to lubricate the inner gears.

56. hop under the car and break off the 8 14mm 12pt flex plate bolts off the block. use the same socket wedging you used to break off the torque converter bolts. remove flex plate

57. now install your flywheel of choice. i just used an oem one but what ever you use, make sure it has a clean, smooth surface. attach by using 8 14mm 12pt

flywheel bolts. tighten down in a crisscross manner. clean the surface the flywheel with brake cleaner. NO!!!!

58. the clutch kit should be up to you. i got a good stg 1 clutch for a good price. install the clutch onto the flywheel via clutch instructions. tighten down the 10mm 12pt bolts in a crisscross manner.

59. back to the tranny, install a new throw out bearing onto the shift fork. position the tranny to be lifted up. double check to see if you have the vss and reverse switch installed

60. get a friend to go under the car and hold the tranny up while you thread a tranny bolt into the block. MAKE SURE that you don't mess with the fins on the clutch. place a jack under the tranny for support to hold up the tranny. you may have to wiggle or kick the tranny onto the engine.

61. start threading the bolts by hand into the block.

62. once you have the majority threaded in, start tightening them down in a crisscross like pattern. MAKE SURE that the tranny goes on straight and not crooked

63. install the tranny mount onto the tranny and onto the wall

64. now screw in the bolts for the rear mount. you may have to jack up or down the tranny jack to line up the holes

65. back to the subframe, make sure the front engine mount is on both the engine and the subframe. do not tighten all the way yet

66. lift up the subframe and start attaching the bolts back onto the car, 6 on the backside, 2 in the front and 4 on the lower control arms. tighten all of them up

67. rebolt the front mount together. then tighten down all the bolts for the front mounts

68. now you can remove both jacks. Take another break. the heavy stuff is done.

69. head under the car again, find the shift cables and route them up to the tranny. to do so correctly, have them go up the firewall, over the rear mount but under the intake manifold.

70. install the shift cable holder onto the tranny via the 3 bolts. install the shifter cables onto the holder via 2 c-clips.

71. slide the ends of the shifter cables onto the shifter forks. MAKE SURE you use some sort of washer and cotter pin if not OEM parts. all you need is to shift on the road and the cables or bushing to pop off

72. install the heat shield again with the 2 bolts and 2 nuts

73. install the dustcover on the underside of the tranny. there may be an issue with one of the bolts not lining up, but the rest should hold it in fine

74. grab a 3/8 ratchet and break loose the drain bolt on the manual tranny again. using a funnel and 1/4" tubing, fill the manual tranny with your choice of tranny fluid. i first used honda MTF but am switching to 50w synthetic for slower shifting. fill it to the point where it overflows a lttle. tighten down nut

75. the intermediate shaft need to be installed onto the block before your new driverside axle can be put in. just slide the shaft all the way into the tranny and match the bolt holes up and install the bolts.

76. now the new driverside axle, first place the axle over the horseshoe strut piece. then slide the axle through the spindle. gently force it all the way into the spindle.

77. now slide the axle into the intermediate shaft. MAKE SURE that it is fully in the intermediate shaft. to do so, take the fat end of a baseball bat and gently hammer it all the way in while turning the axle. there can not be almost any gap. gaps equal popped out axles.

78. CAREFULLY place the spindle ont the lower control arm. if you break the ball joint, it will need to be replaced. tighten it down with the castle nut. line up the hole with the castle nut and slide the cotter pin through. it will be a pain to do, but must be done.

79. take the axle nut and tighten down hand tight. DONT PUNCH THE TAB YET!

80. go to the passenger side and follow the same steps.

81. install any splash shields you took off

82. now head up top and start putting stuff back on. reinstall the distributor with 2 bolts and plug it in

83. get a new starter that matches your year and tranny. MAKE SURE the o-ring terminal is on good and tight and that little plug is connected as well

84. break out the tangle web of line tht is you clutch fluid line. screw in one end to the master cylinder. its a pain to get on but it will go on. get it good and tight.

85. run the lines behind the intake manifold and up to the slave cylinder. screw the other end to the slave cylinder.

86. go back to the master cylinder and hook up the clutch fluid reservoir. if you want to attach it to the firewall go ahead, but mine is just sitting there upright

87. take a look at the radiator. you will see 2 tubes coming out of the bottom of the radiator. these went to your old auto tranny and are not needed anymore. make a loop out of one of the tubes.

88. place the radiator back in. MAKE SURE that the rubber feet are sitting in the seats. attach the top of the radiator to the frame with the 2 10mm bolts

89. install the bottom radiator hose then the top radiator hose. make sure the clamps are on good and tight

90. attach the overflow tank on the radiator

91. time to add some coolant to the radiator. fill it up and add some to the overflow. you may have to add some LATER after you have driven the car some

92. bleeding the clutch is fairly easy. bleeding brand new clutch lines aint. to prime your new lines you will need to buy an actual brake bleeding tool. i made my own out of a cheap bilge pump. take a some generic brake fluid and poor some into the clutch reservoir, leave the cap open. open the 8mm bleed screw with a wrench and place the pump on the bleed screw and start pumping the air out. but be careful that the reservoir doesn't get too low and you start pumping air in the line. once it is primed, close the screw and remove the pump.

93. i recommend you bleed the clutch the right way to make sure there is no air in the line. go to the slave cylinder and find the bleed screw again. place wrench on screw then attach a vacumm hose to open bleed screw leading to a cup of brake fluid, make sure the line is in the fluid, not out of it. add fluid to reservoir, then go to the inside and follow this procedure, clutch pedal pushed in > close bleed screw > lift up clutch pedal > open bleed screw. follow these steps a few time to make sure all the air is out. close screw and check fluid level in reservoir then cover.

94. wait to install the intake and battery till we are done with the wiring. clean up and take your last break of this project hopefully.

NOTE: ALL WIRING MUST BE SOLDERED TOGETHER!!! FAILURE TO DO SO WILL CAUSE YOUR CAR NOT TO WORK CORRECTLY!

95. the easiest thing to do as far as wiring is to locate the big tranny plug in the engine bay. find the grey and red wire on the plug. strip and solder these 2 wires together. wrap with electrical tape

96. test car to see if car turns over. if it does, CONGRATS......... YOU JUST DID IT

_____________________________________________________________________________

VSS Wiring

This is a simple fix to make the vss/vtec work. if you want to edit this to make it work better, have at it.

lets use this pin diagram:

http://www.driveaccord.net/forums/at...5&d=1111724327

depin the #10 on connector D and install onto 23 on connector C. depinning is a ***** but it must be done for your sake. as far as the vss, i cant confirm wire colors, but when you are looking at the plug, with the clip part on top, the wiring is as follows... ground / power / signal.

now the speedo has to be tee'd off. the auto got an input from the vss to the ecu the sent another signal to the speedo. somewhere along your vss signal line, splice the wire with the blu/wht wire running to the back of your speedo. the other end, not connected to the cluster, is on the pass side behind the fuses.

I CAN NOT PROVIDE WIRING DETAILS ON MY CAR. SINCE I SWAPPED TO OBD-I, MOST OF THE WIRING I DID WILL NOT WORK WITH YOUR CAR. PLEASE USE OTHER WIRING DIAGRAMS FOUND ON THIS THREAD.

thanx to turbowa, s.cali alan, drift, stinker504

DO NOT REPOST WITHOUT PERMISSION

Thanks for lookin

Last edited:

![image 133[1] (2)](/forums/data/xfmg/thumbnail/0/56-6ca9e7d3be5e1b155e3f787aec2ef7f0.jpg?1695467876)